Aluminum jaw couplings are a type of flexible coupling that offer several features and benefits, including:

Lightweight: Aluminum jaw couplings are lighter than many other types of couplings, making them ideal for applications where weight reduction is important.

Corrosion resistance: Aluminum is highly resistant to corrosion, making aluminum jaw couplings well-suited for use in harsh or corrosive environments.

Low noise: Aluminum jaw couplings have a high damping capacity and low noise characteristics, making them ideal for use in noise-sensitive applications.

High torsional stiffness: Aluminum jaw couplings provide high torsional stiffness, which helps to maintain accuracy and precision in applications where shaft misalignment is a concern.

Easy installation: Aluminum jaw couplings are typically easy to install and maintain, which can reduce downtime and increase productivity.

Cost-effective: Compared to other types of couplings, aluminum jaw couplings are often more cost-effective, making them a cost-efficient option for many applications.

Flexible design: Aluminum jaw couplings are designed to accommodate misalignment, vibrations, and shock loads, making them ideal for use in applications where shaft alignment is not perfect.

Durable: Aluminum jaw couplings are designed to be durable and long-lasting, even under harsh operating conditions.

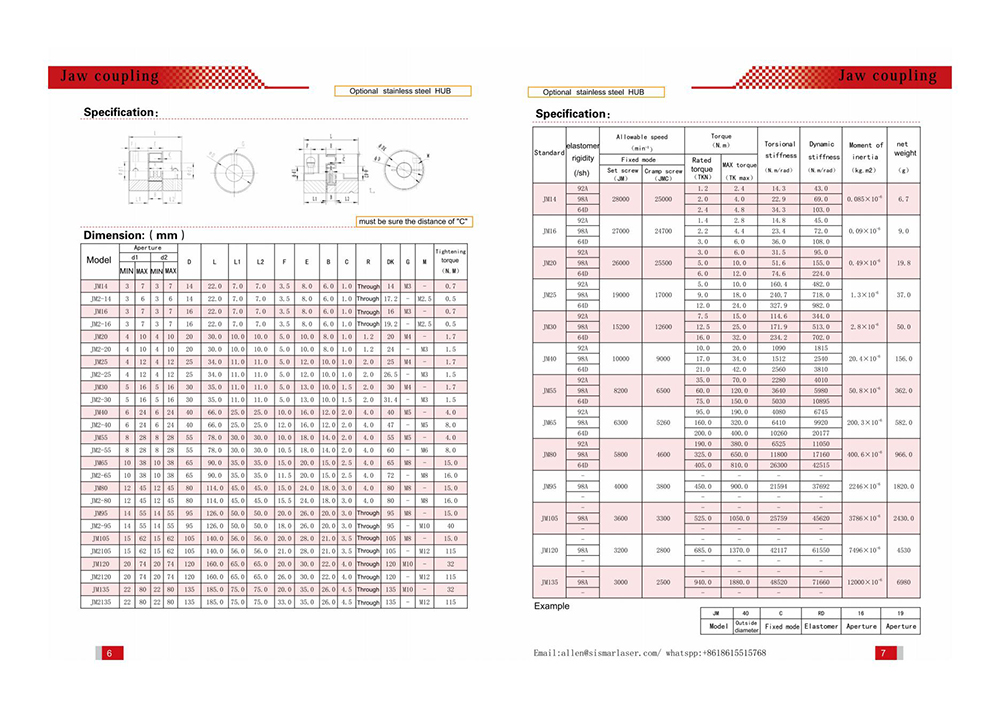

Technical information