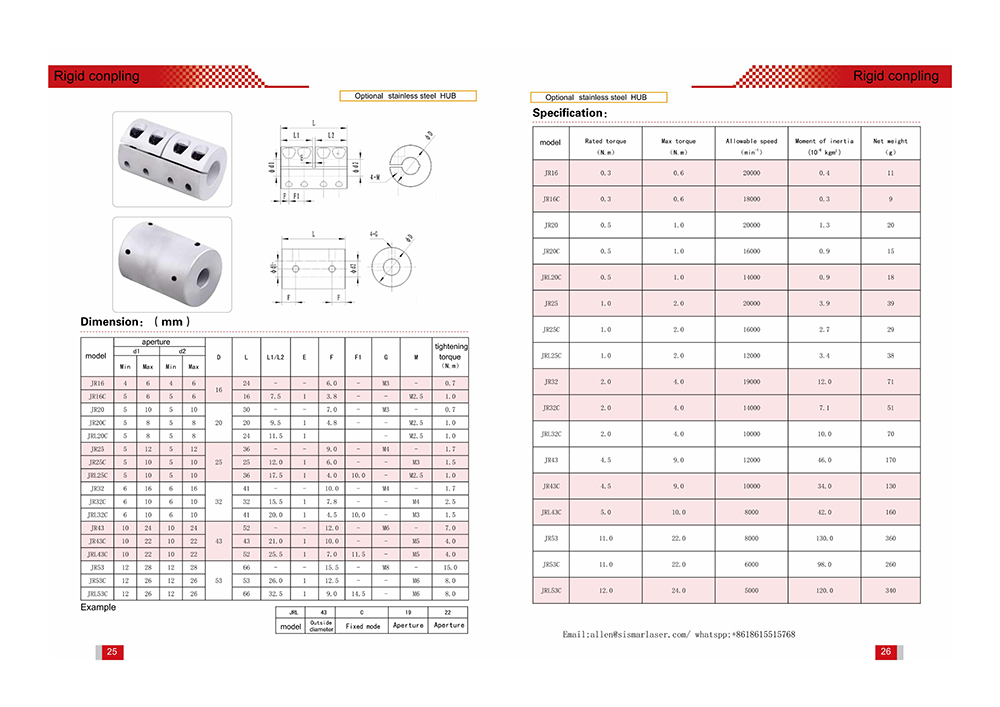

Rigid couplings are commonly used in a variety of applications where high rigidity and precision are required. Some common applications of rigid couplings include:

Machine tools: Rigid couplings are used in machine tools, such as lathes and milling machines, where precise positioning and accuracy are important.

Robotics: They are used in robotics applications, where precise motion control is required and where shaft misalignment is a concern.

Aerospace: Rigid couplings are used in aerospace applications, such as aircraft control systems, where precise positioning and accuracy are important.

Medical Equipment: They are used in medical equipment, such as X-ray machines and CT scanners, where precise positioning is required.

Instrumentation: Rigid couplings are used in instrumentation, such as spectrometers and balances, where precise positioning is required.

High-speed applications: Rigid couplings are ideal for use in high-speed applications where precise positioning and accuracy are important.

It is important to note that the specific requirements of an application will determine the best type of rigid coupling to use. Factors such as the size and power of the equipment, the operating environment, and the specific performance requirements should be considered when selecting a rigid coupling. Rigid couplings may not be suitable for applications where shaft misalignment is present or where movement between the shafts is required.